-

Comprehensive EMS solutions:- quick response- no minimum ordering quantity- flexible and modern production

Comprehensive EMS solutions:- quick response- no minimum ordering quantity- flexible and modern production -

Let us take care of your products.more about us

Let us take care of your products.more about us -

Protoypes when you need them.quick serviceDelivery period: 3 days for printed matter and quickly deliverable matter + 3 days for production

Protoypes when you need them.quick serviceDelivery period: 3 days for printed matter and quickly deliverable matter + 3 days for production

Development of Electronics and Optimisation of PCB for Production

Due to our long-standing experience with electronics, we can help our clients develop electronics in accordance with their wishes and requirements. We also offer the service of PCB redesign to meet the changed functionality requirements for more efficient serial production (DFM – “design for manufacturing”).

Material Procurement

With our extensive network of business partners, we can offer competitive prices and find critical components. We strive to ensure an optimal price in accordance with the required delivery date.

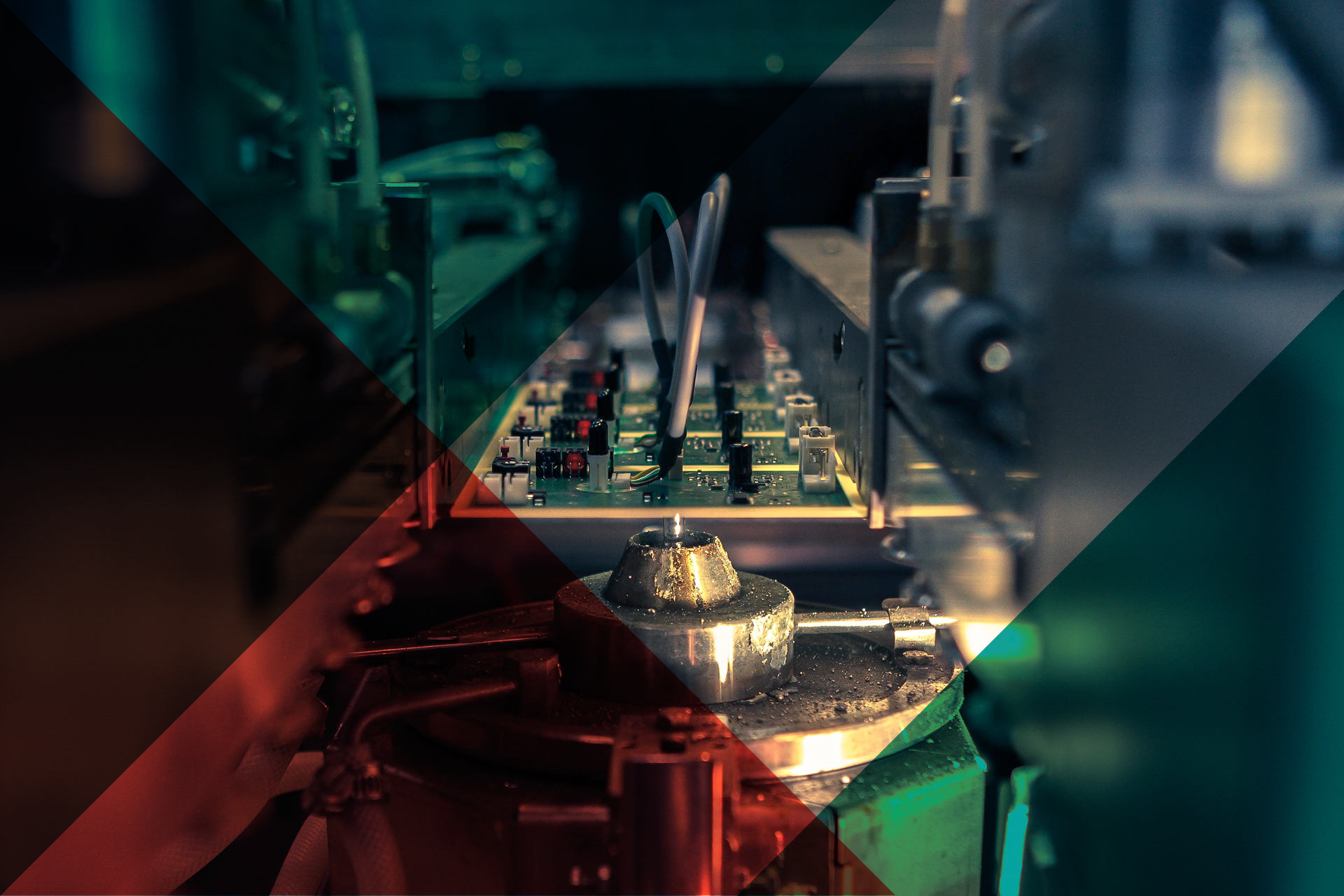

Own PCB Production at the Sister Company

We can provide quick delivery of bare PCBs, because we are connected to Inectiv, the largest PCB manufacturer in Slovenia, and more flexible and prototypically oriented company Elgoline. The partner companies of our group can provide flexibility and good quality control.

Component Placement on PCB

Our production allows for services such as SMD and THT component mounting and also additional services, such as box build. The entire process undergoes consistent quality control and clearly defined processes that enable flawless dispatch in the required period.

Box Build

We also offer the possibility of product programming and testing, when the client is able to provide the test device or it is developed in Proplace. Final products may also be mounted in the casing.

Packaging and Logistics

We are glad to satisfy the requirements of our clients with regard to the packaging and dispatch of products to the desired location.